-

Q01Please tell me the differences amongst the three KATANA Zirconia series.

Each one of the series has different levels of translucency and unique mechanical properties.

UTML: This one is the most translucent of the three series and is most suitable for fabricating anterior crowns or laminate veneers. Restorations can achieve a beautiful esthetic appearance with just simple external staining and glazing. This product is also an excellent choice for up to a three unit anterior bridge.

STML: This product benefits from a well-balanced combination of translucency and mechanical properties.

It has gradations of translucency as well as color, exhibiting an esthetic masking effect in the cervical area. Using this series, you can easily obtain the desired final restoration shade over the various tooth stump shades typically found in clinical cases. Additionally, the mechanical properties of STML make it an ideal choice for up to a three unit posterior bridge.

HTML: This product boasts an excellent high mechanical strength, and thus is suitable for the fabrication of bridges and frameworks, including full-span arch rehabilitation cases.

-

Q02What is the crystal structure?

HTML has bigger ratio of tetragonal and STML and UTML has ratio of cubic.

-

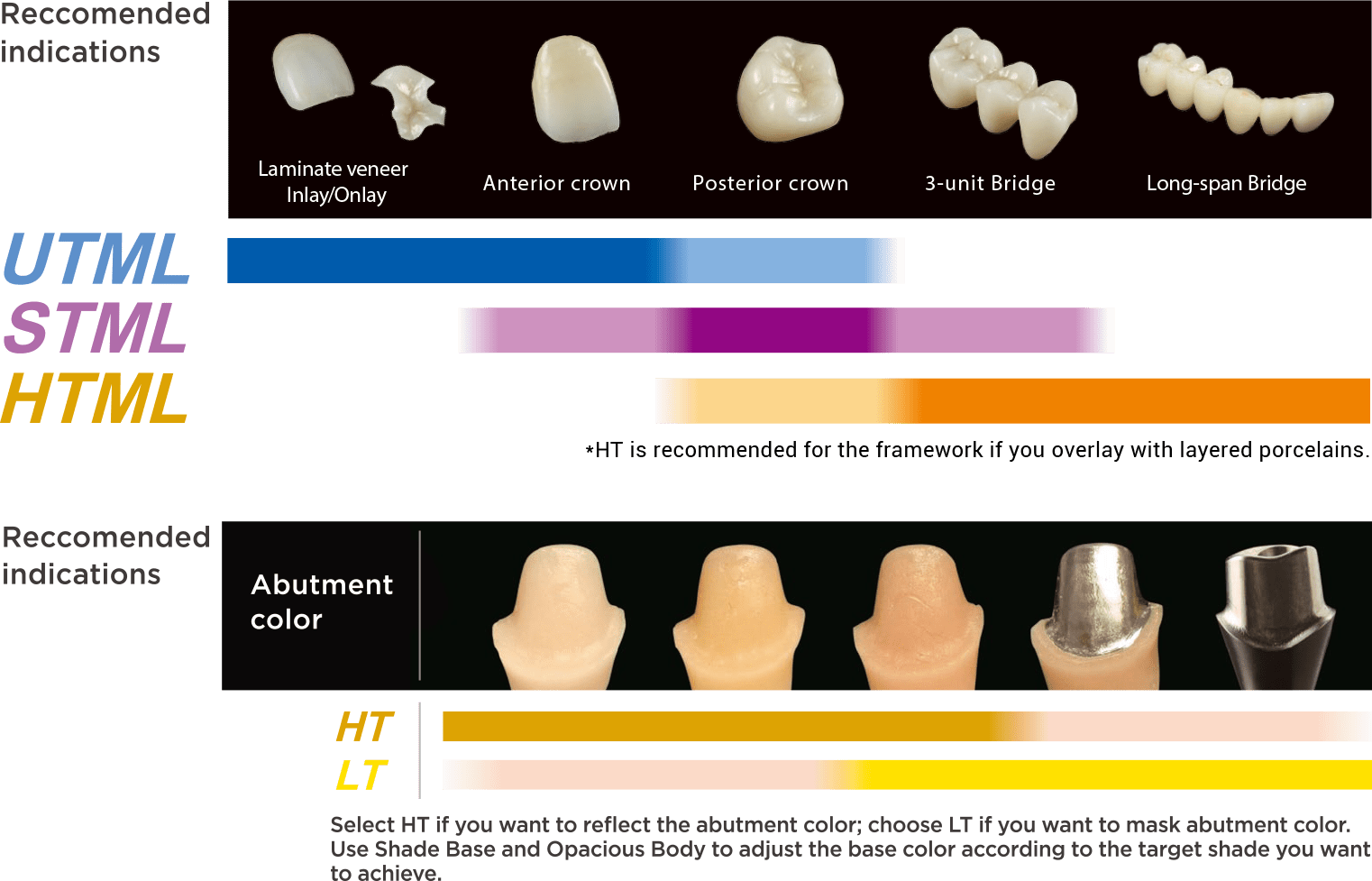

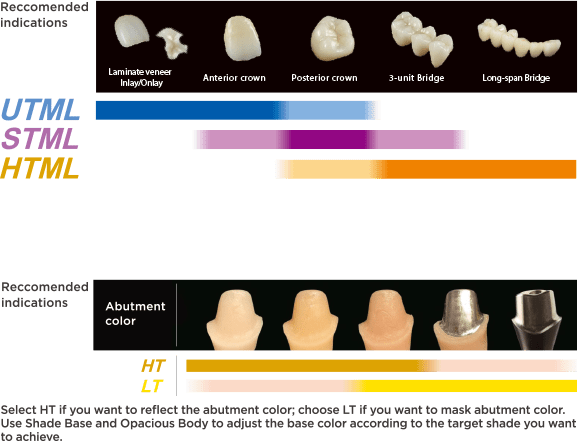

Q03Please tell me the recommended and indicated applications.

The recommended and indicated applications for each series are:

-

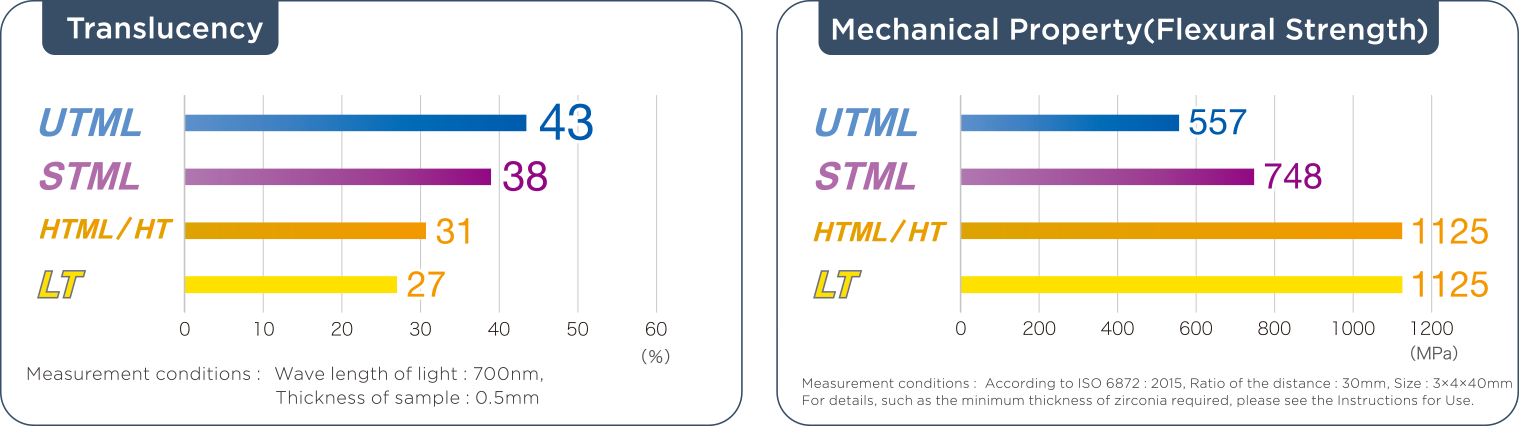

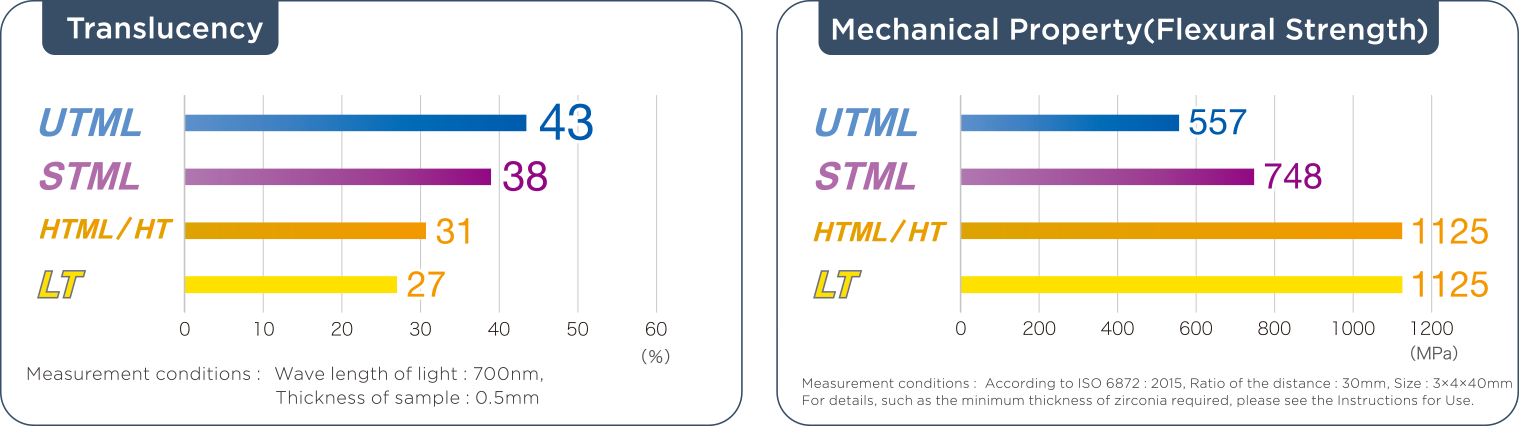

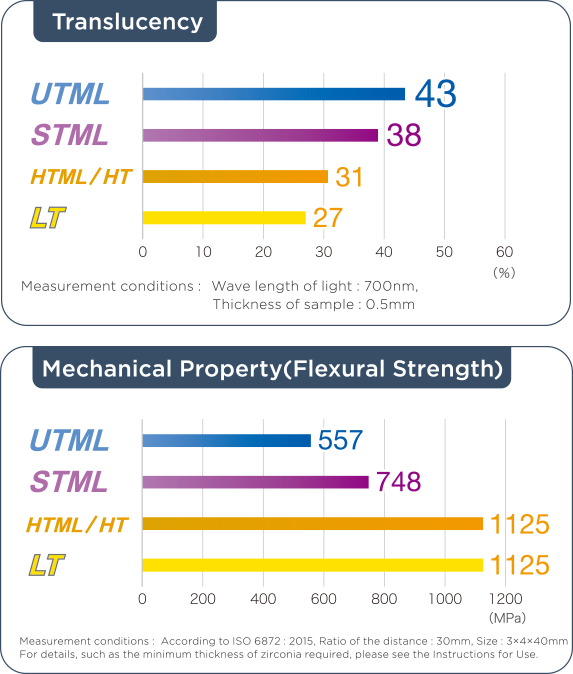

Q04Please tell me the differences in mechanical properties

amongst the KATANA Zirconia series.

Each series has the following mechanical properties and levels of translucency:

Date sourse: Kuraray Noritake Dental Inc. The numerical value varies according to the condition.

Date sourse: Kuraray Noritake Dental Inc. The numerical value varies according to the condition.

-

Q05How do UTML and STML achieve their high levels of translucency?

Do they contain glass ceramics?

They do not contain glass ceramics. Their high translucency has been achieved through a new type of zirconia powder which we developed using our own unique technology.

-

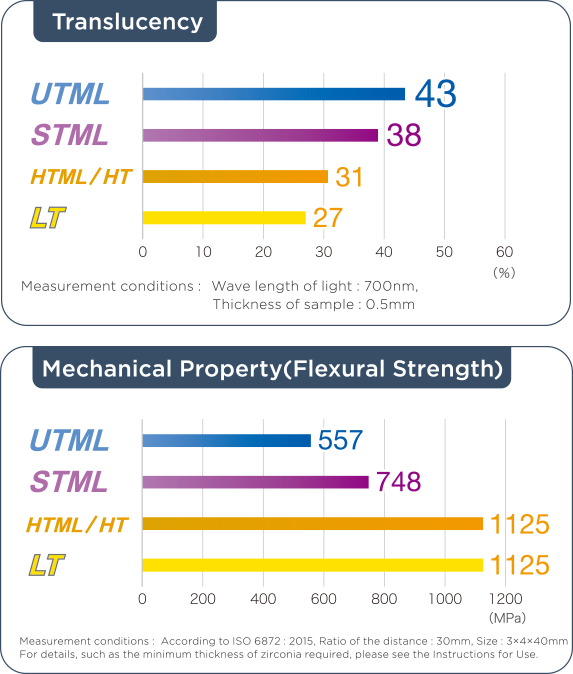

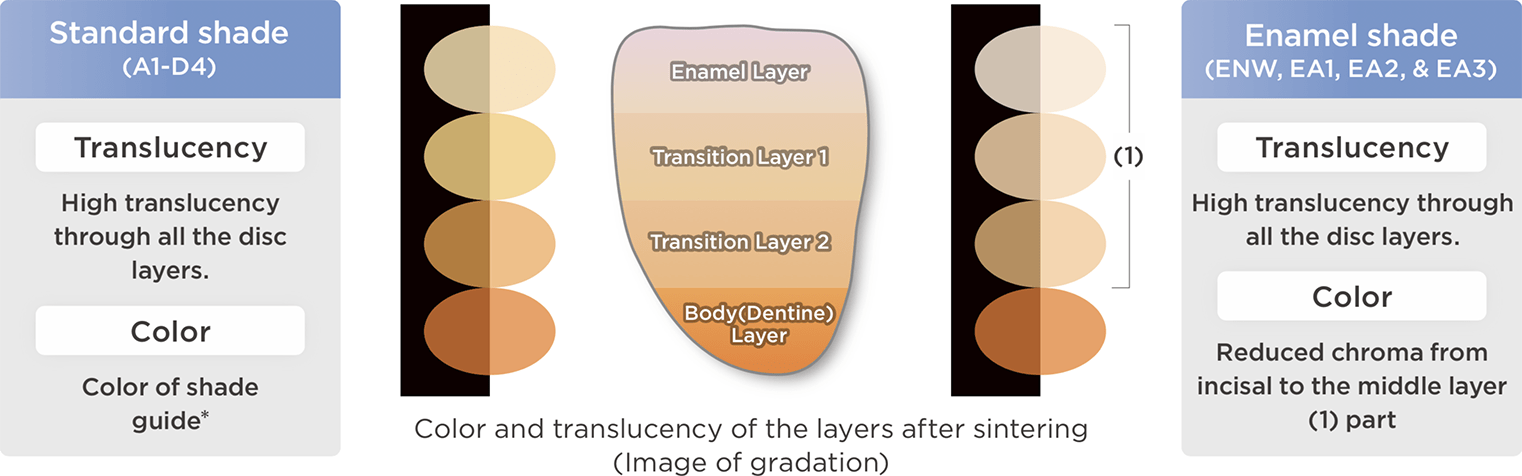

Q06How many color transition types are available in the UTML series?

A. UTML comes in two color transition types: the “Standard Shades” and the “Enamel Shades”.

Each type has a high level of translucency through all the disc layers.

The Enamel Shades have reduced chroma in the upper layer, which allows you to enhance the translucency of the incisal area freely, where needed, by staining.

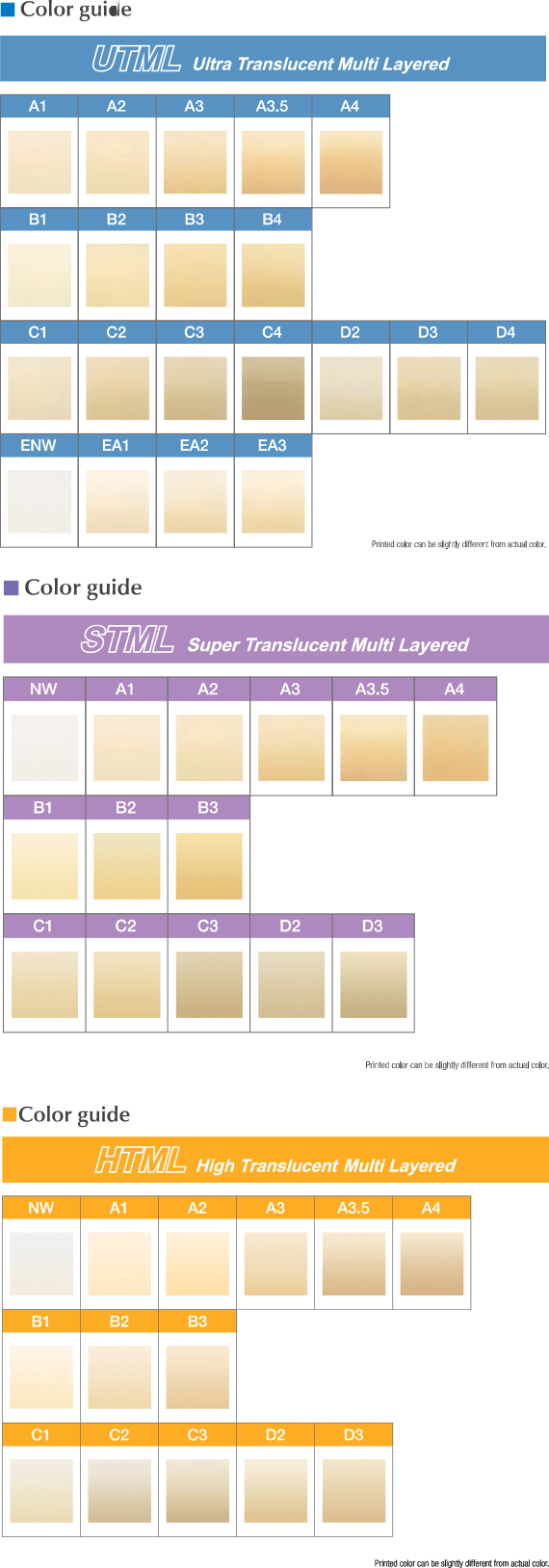

UTML Shades

There are two different shade groups: “Standard Shades” and “Enamel Shades”. Enamel Shades have reduced chroma in the upper layer (1) which allows you to enhance the translucent appearance of the incisal area, as desired, by utilizing external stain characterization.

*VITA Classical Shade Guide

*VITA Classical Shade Guide

-

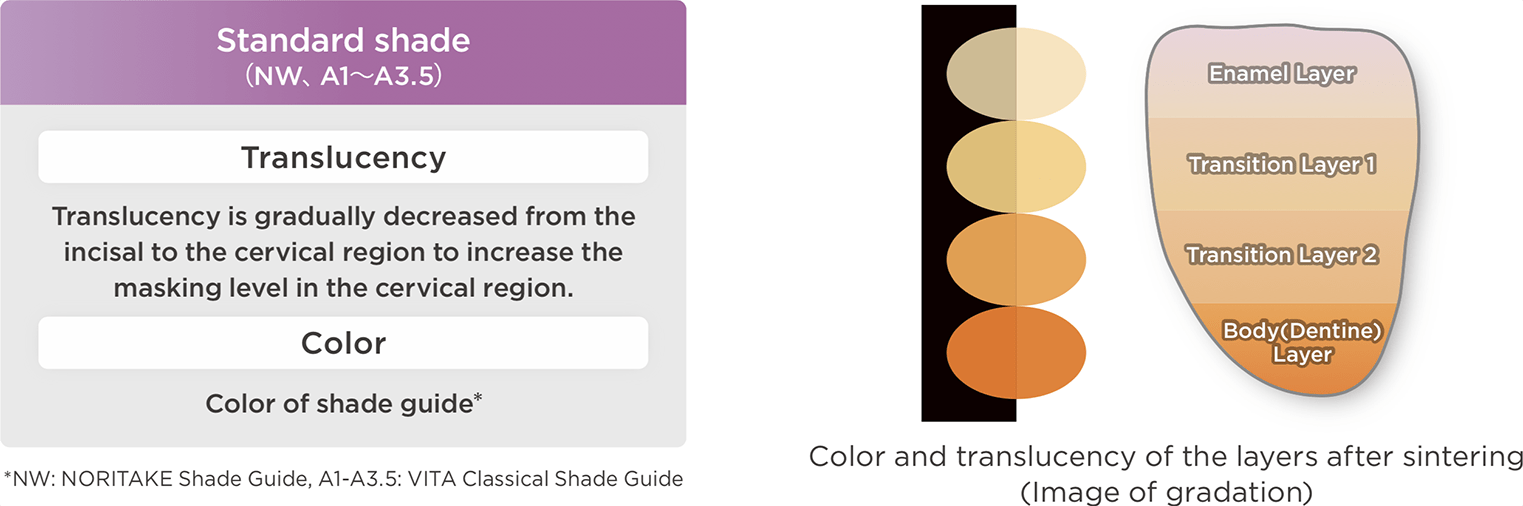

Q07How many color transition types are available in STML?

STML has only the one Standard Shade type. It does, however, also have gradations of translucency. With this additional masking effect in the cervical area, STML will accommodate a wider range of prepared tooth stump shades than UTML.

STML Shades

A well-balanced combination of chromatic and gradational translucency reproduces esthetic enamel and dentin effects.

-

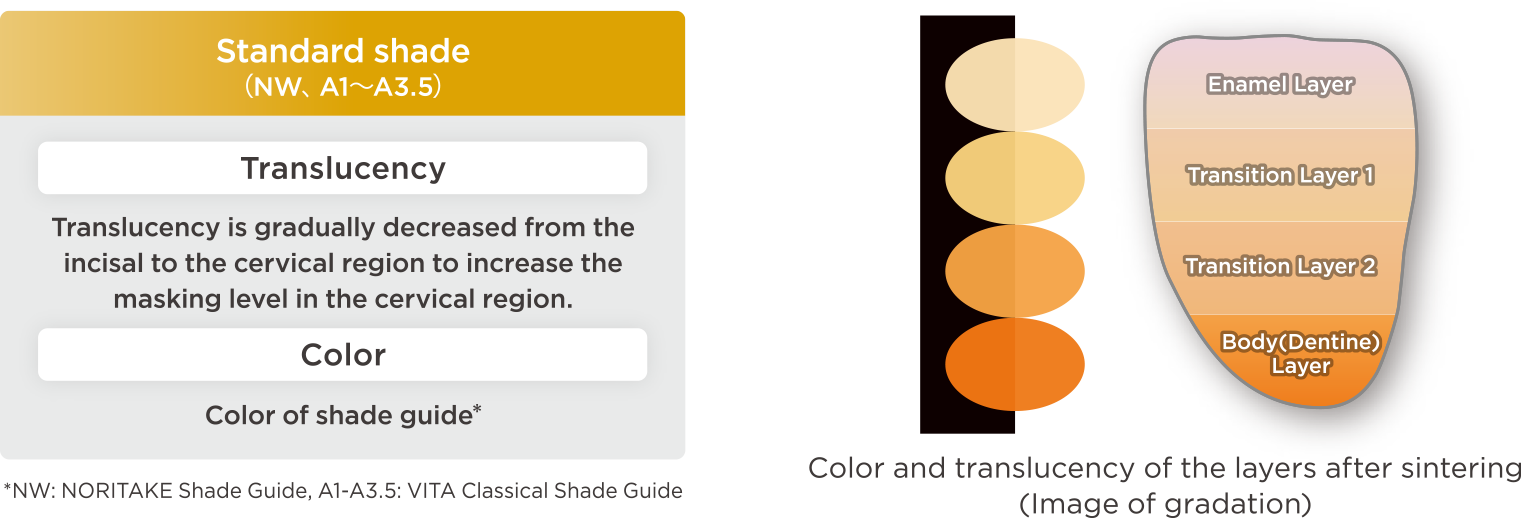

Q08How many color transition types are available in HTML?

HTML has only the one Standard Shade type.

The masking ability of the HTML is well-balanced, due to its good level of translucency with gradation of the color.

-

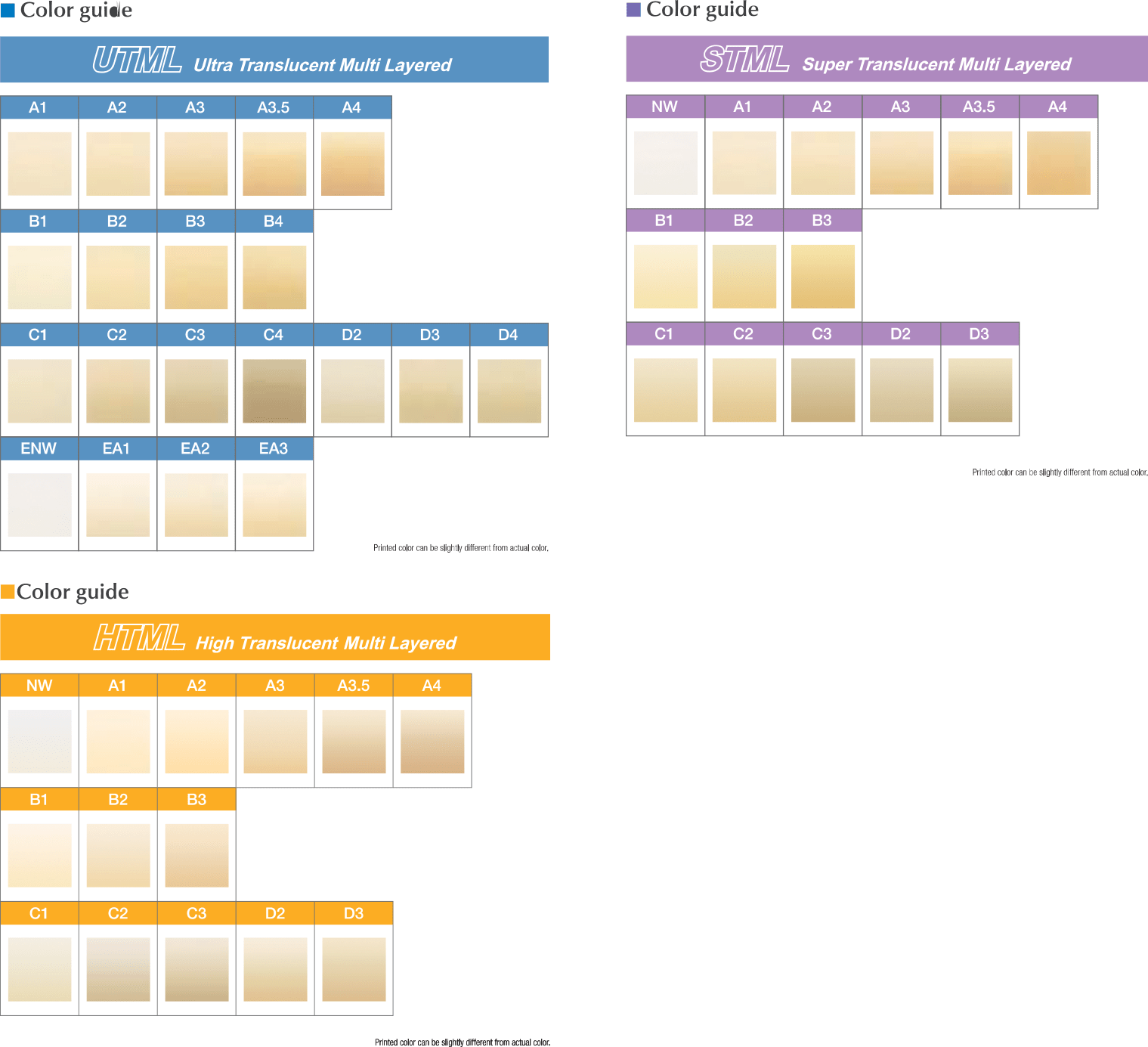

Q09How many shades are available for both UTML and STML and HTML?

UTML is available in 20 shades; STML and HTML is in 14 shades.

-

Q10What are the shapes of the discs in the series?

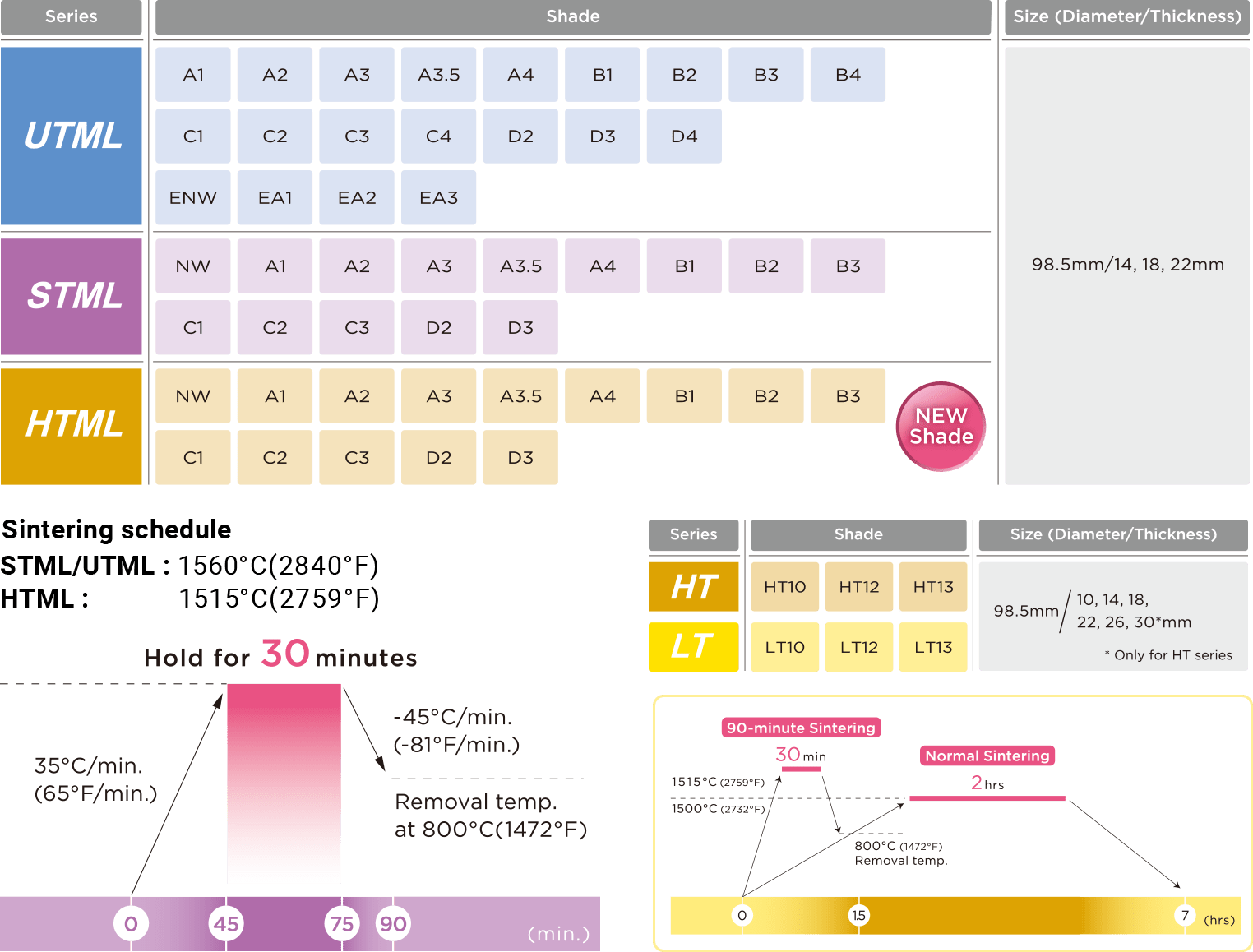

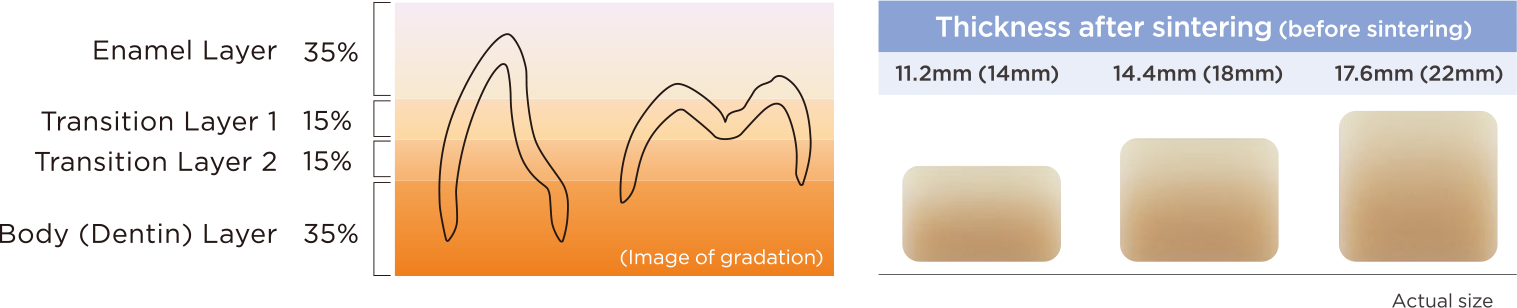

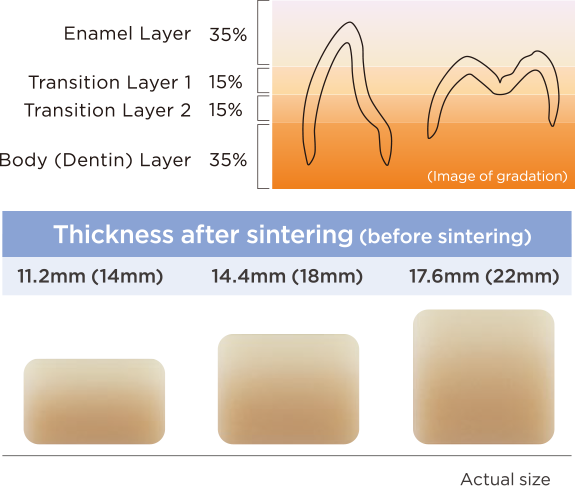

Each series is supplied in the form of a flat 98.5 mm diameter disc that has a 10mm-wide plastic ring collar. You can select the appropriate disc thickness, according to the crown length needed for each clinical case. Disk thicknesses are 14, 18, and 22mm.

-

Q11How can I tell the right side from the wrong side of the disc

when I am placing it in the milling equipment?

The side with an “occlusal surface” sketch imprinted is the upper layer (the enamel layer).

-

Q12Is it possible to adjust the vertical location of the gradation to suit each clinical case?

Yes, you can do this utilizing various CAM software options. These options allow the designer to change the crown position within the disc profile to achieve the best gradation map for the restoration. Please refer to our “Handy Chart” for guidance.

-

Q13Can I use a wet milling machine for KATANA Zirconia?

It is not recommended for you to use a wet milling machine for KATANA Zirconia, as it will not achieve the desired esthetic effect.

-

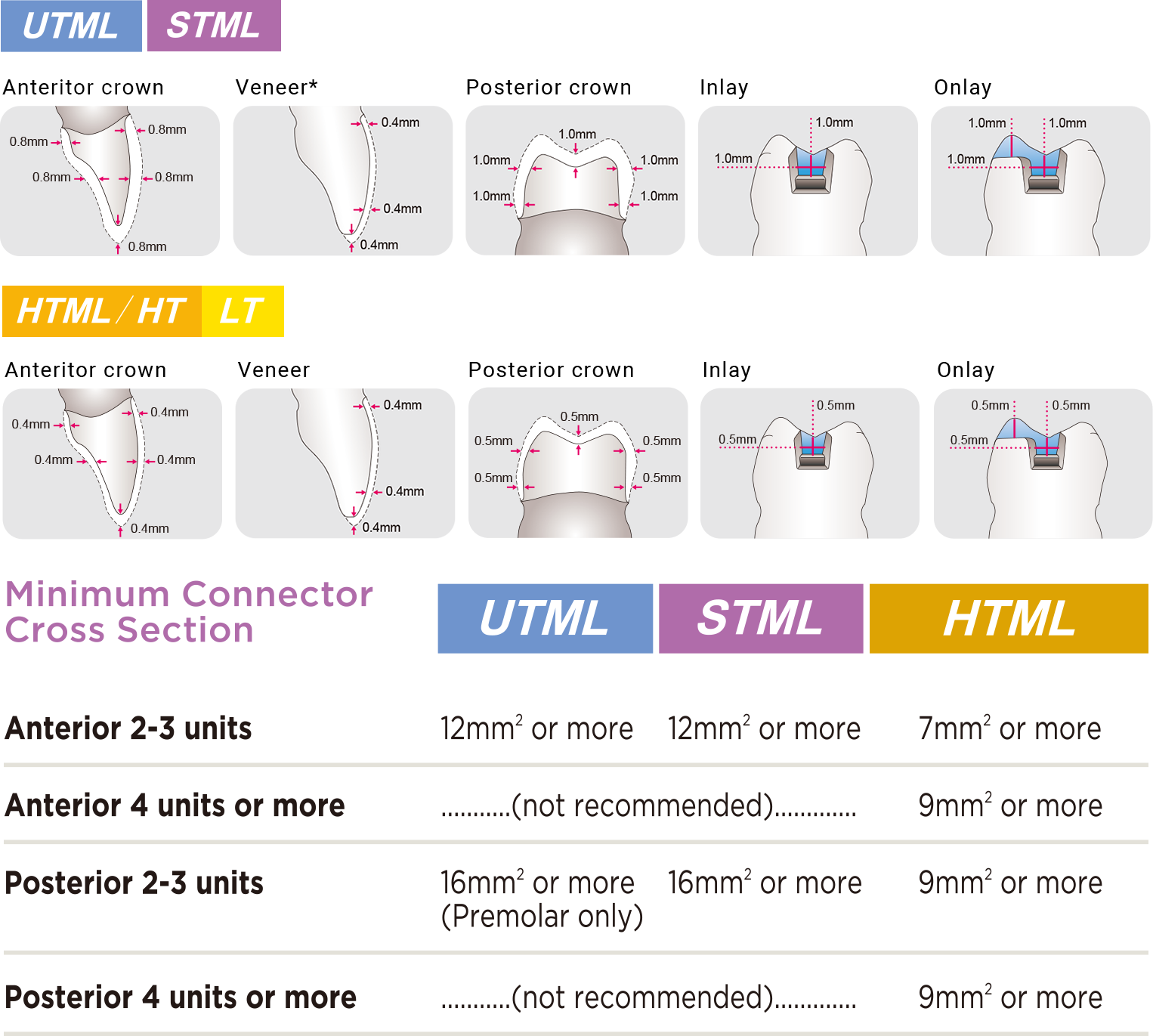

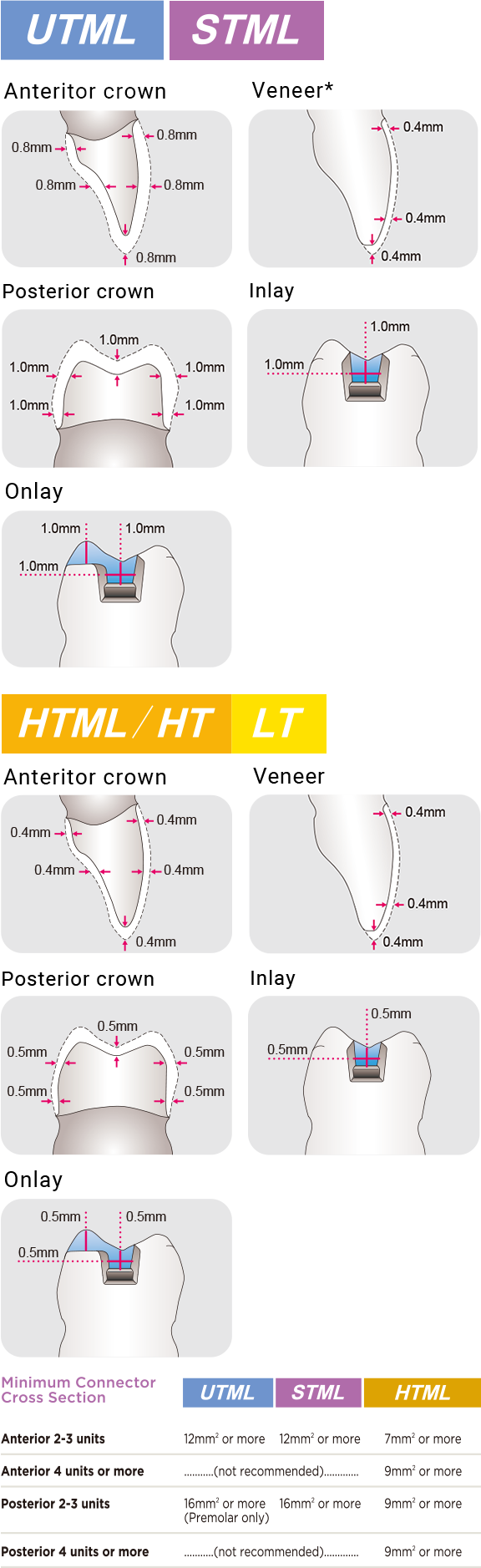

Q14What should I keep in mind when designing restorations using STML or UTML?

In case of using UTML or STML, you need to have a minimum wall thickness of 0.8 mm for anterior teeth and 1.0 mm for posterior teeth. HTML need to have a minimum wall thickness of 0.4mm for anterior teeth and 0.5mm for posterior teeth. It is also important to have the mentioned minimum thickness when you do cut-back for a porcelain overlay.

The maximum number of connected units should be limited to three anterior teeth (including a premolar) for UTML bridges and up to three posterior teeth for STML bridge. Additionally, you must provide the specified minimum connector size for each: 12 mm2 for anterior bridges and 16 mm2 for posterior bridges. If you want to make over 4-unit bridges, you choice HTML. you must provide the specified minimum connector size for each: 12 mm2 for anterior bridges and 16 mm2 for posterior bridges.

The recommended and indicated applications for each series are:

Mimimum Wall Thickness of Zirconia

-

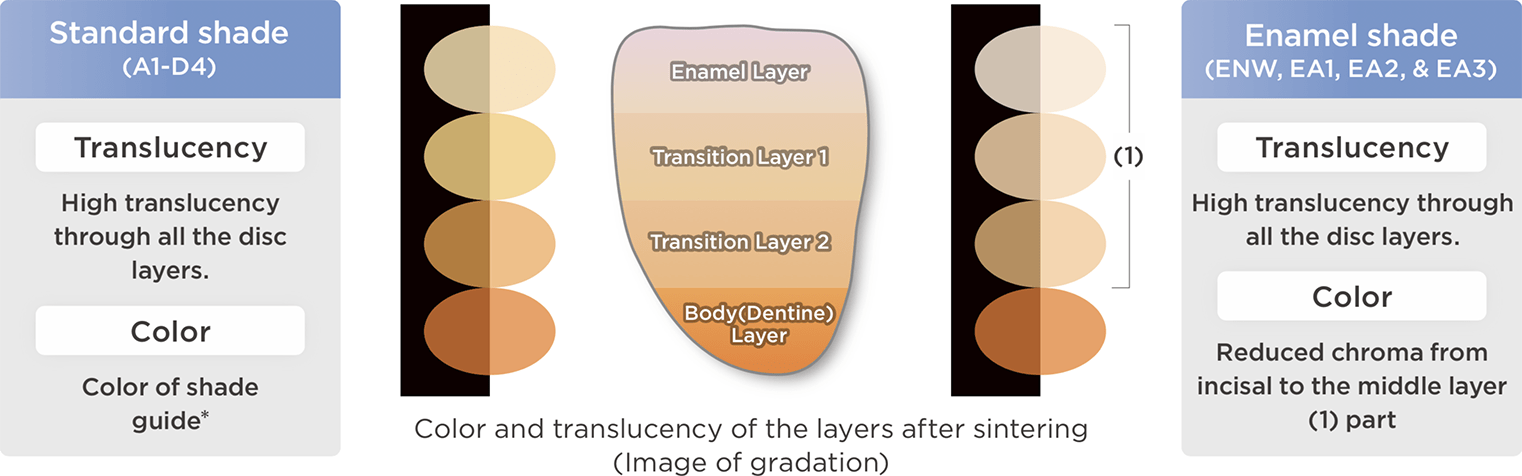

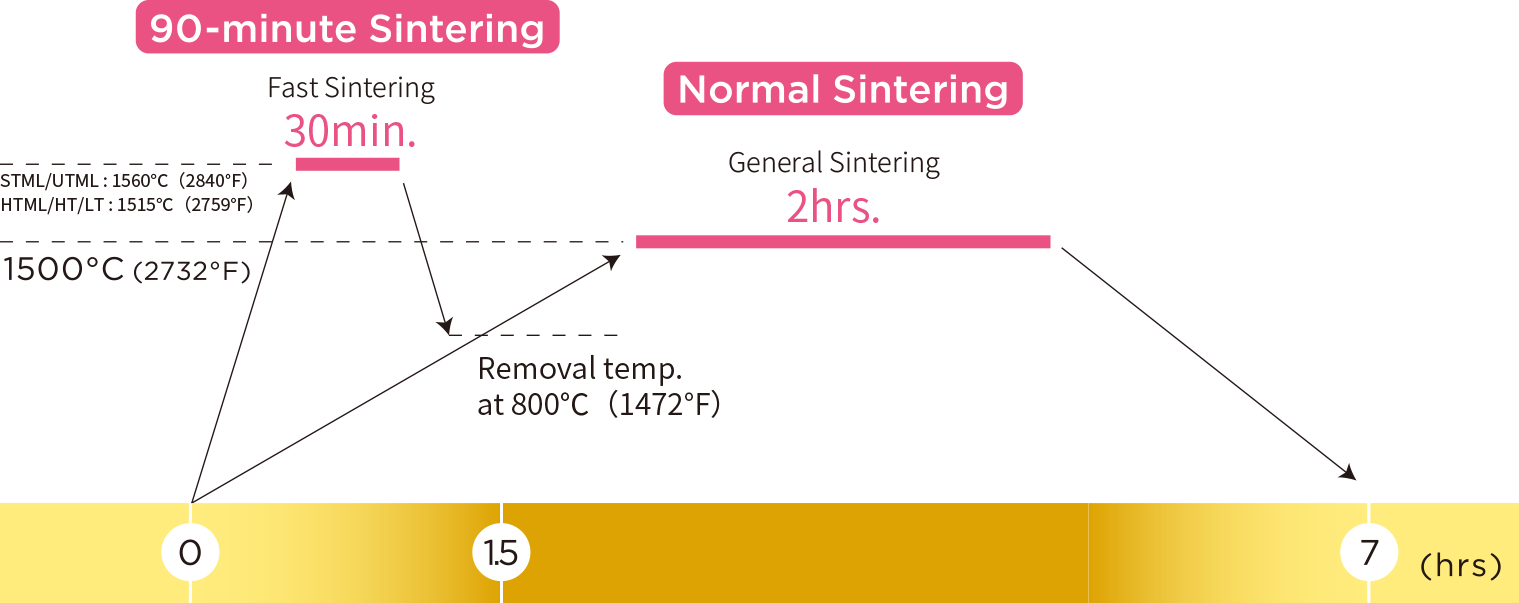

Q15Are the sintering schedules for UTML and

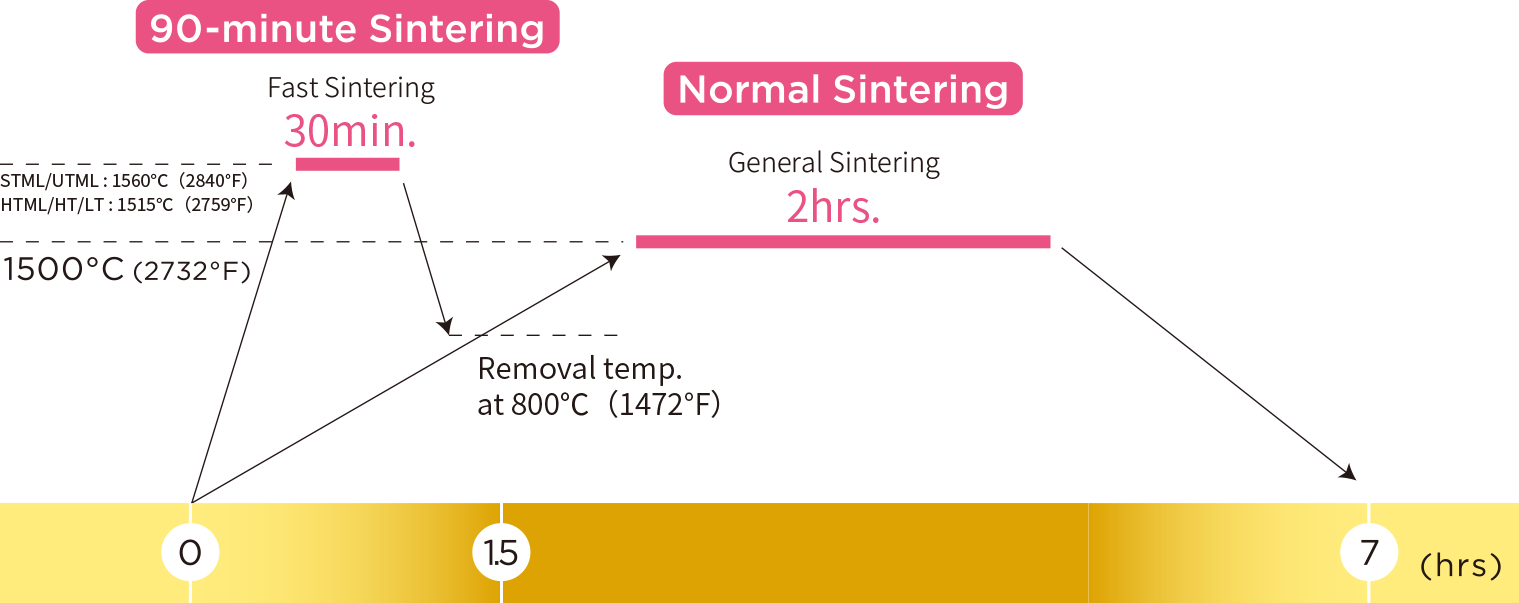

STML the same as other existing zirconia products?

They are different from those of other manufacturer’s zirconia products, and of our own conventional ML/HT product. The high sintering temperature for UTML and STML is 1550°C (2822°F) , HTML is 1500 (2732°F) and the total sintering time is 7 hours.

In addition to the usual sintering time (approx.. 7hours), due to our proprietary zirconia technology, KATANATMZirconia can be sintered in approx.. 90 minutes* without compromising translucency or mechanical strength.

*The material is removed from the furnace at 800. It is possible to fast sintering up to up to a 3-unit bridge.

Sintering Schedule

STML/UTML : 1560°C(2840°F)

HTML/HT/LT : 1515°C(2759°F)

*The material is removed from the furnace at 800°C, and is for Up to a 3-unit Bridge.

*The material is removed from the furnace at 800°C, and is for Up to a 3-unit Bridge.

-

Q16What points should be kept in mind when removing a restoration from the furnace?

To prevent the restoration from being cracked, remove it from the furnace at 800°C and leave it on a heat sheild material such as a refractory material or glass wool until it gets cold to room temperature.

-

Q17What is newl shade of HTML?

14 shades are prepared. Please refer to the brochure. It is set to be the target color when using glaze for finish. For polished finish, please select a lighter shade.

-

Q18Regarding the rapid sintering, is it possible to sinter 3-unit bridges?

Yes, you can. Now 90-minute sintering is possible for 3-unit bridges.

-

Q19What kind of sintering furnace can be used? Can I use a sintering furnace

with a maximum sintering temperature which does not reach 1550°C (2822°F)?

You cannot achieve the specified level of translucency or color development if the furnace cannot maintain 1550°C (2822°F) for at least 2 hours. If the framework was not sintered well at 1550°C (2822°F), the layered porcelain over the framework may have a risk of developing cracks. You can use any sintering furnace that can sinter at 1550°C(2822°F), regardless of the manufacturer.

*If the maximum sintering temperature of your furnace is 1550°C (2822°F), please ask the manufacturer if it can be used at that temperature for a 2 hour hold time.

-

Q20What points should I keep in mind when handling restorations after sintering?

UTML’s and STML’s mechanical properties are similar to those of glass ceramics. For this reason, you should always grind them at a low rpm with a water cooling spray, being careful not to apply strong pressure. Diamond points can be used to grind, however, do not use diamond discs that can create deep cuts. If it becomes too deep, it increases the risk of cracks.

-

Q21How should I finish the restorations?

You can finish them by glazing, staining or applying a thin layer of porcelain. You can use any of the following products for finishing, but do not mix them, otherwise, the different coefficients of thermal expansion(CTE) of the materials might cause cracks:

-

Q22Can I finish the restorations by polishing them?

Yes, you can. You can easily achieve the desired lustrous finish by using Pearl Surface Z. UTML and STML are developed to finish by glazing to achieve the desired shade. If they are finished by polishing only, the final shade will develop increased chroma and appear to be a little darker than the targeted color. We recommend selecting the disk to be milled one shade brighter than the targeted finished restoration shade when polishing.

-

Q23Can I use any of other manufacturer’s coloring liquids on

KATANA UTML or STML Zirconia?

This is not recommended, as you. will not be able to achieve your desired level of translucency or color development. However, our conventional zirconia product HT10 can be shaded using the coloring liquid techniques.

-

Q24Can I adjust restorations in the oral cavity?

Yes, you can. It is recommended to polish well after the occlusal adjustment is done chairside to prevent the possible wear of the opposing tooth.

-

Q25After sintered restration, white spots occurred on the surface of restoration..

What is the cause?

When a restoration is polluted, it causes white spots before sintering. Oil from finger, air gun and silicon point

residual substance of a silicon point and the scanning spray is considered as a cause. Be careful not to contaminate the restoration.

Date sourse: Kuraray Noritake Dental Inc. The numerical value varies according to the condition.

Date sourse: Kuraray Noritake Dental Inc. The numerical value varies according to the condition.

*VITA Classical Shade Guide

*VITA Classical Shade Guide

*The material is removed from the furnace at 800°C, and is for Up to a 3-unit Bridge.

*The material is removed from the furnace at 800°C, and is for Up to a 3-unit Bridge.